Welcome to A-Tech Laser

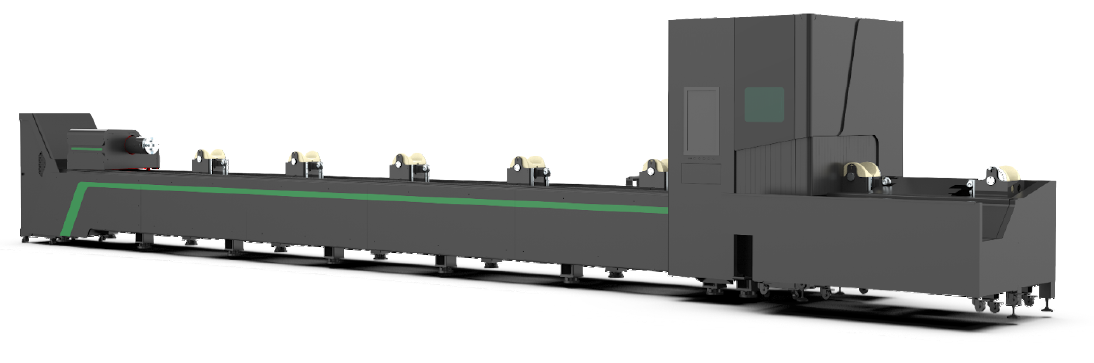

At A-Tech Laser, we specialise in providing advanced laser cutting services for parts, designed to meet the diverse needs of various industries. With state-of-the-art technology and a team of experienced professionals, we ensure precision, efficiency, and quality in every project.

Our Services

1. Custom Laser Cutting for Parts: Our cutting-edge laser systems allow us to cut parts of various shapes and sizes with unparalleled accuracy. Whether you need complex geometries or simple cuts, we deliver with precision.

2. High-Speed Production: Our advanced machinery enables high-speed production without compromising on quality. This ensures that we can handle both small and large volume orders with ease.

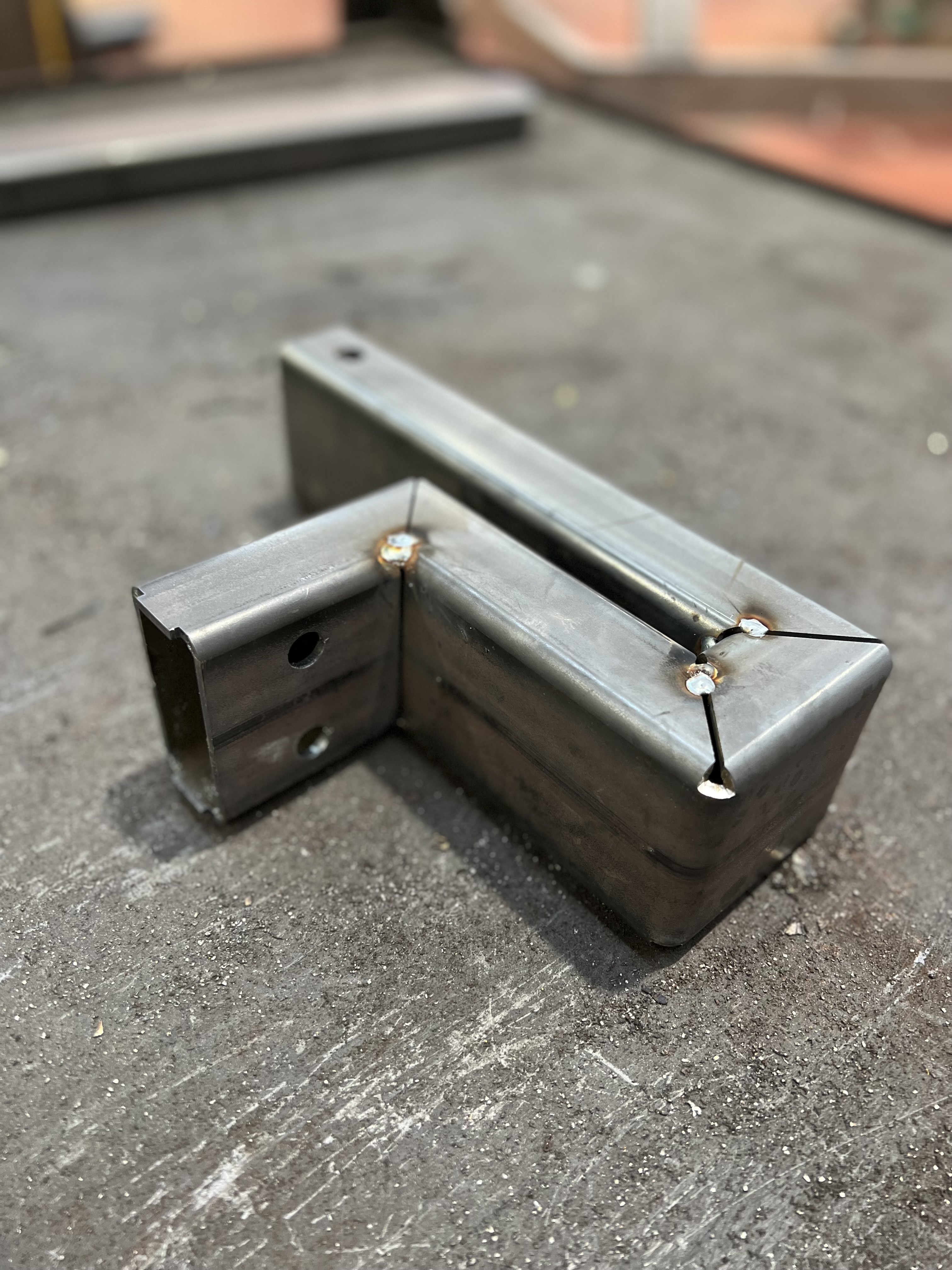

3. 3D Profiling: We offer 3D profiling services to create intricate and detailed parts, meeting the highest standards of design and functionality. Our technology allows for precise 3D cuts, bringing your designs to life.

4. Prototyping and Design Assistance: We offer comprehensive support from concept to completion. Our experts assist with prototyping and design, ensuring your product is optimised for laser cutting.

5. Material Versatility: We work with a wide range of materials including stainless steel, aluminium, carbon steel, and more. Our versatile capabilities allow us to cater to various industry requirements.

6. Secondary Operations: In addition to laser cutting, we provide secondary operations such as bending, welding, and assembly to deliver a complete, ready-to-use product.

Laser Specification

Here, you can see the maximum and minimum dimensions A-Tech has to offer..

-

Raw material max load length – 7.8m

- Finished part max length – 4m

Cutting Capacity Chart

| Material | 3kW |

|---|---|

| Carbon Steel | 12mm |

| Stainless Steel | 8mm |

| Aluminium | 5mm |

| Brass | 2mm |

| Copper | 3mm |

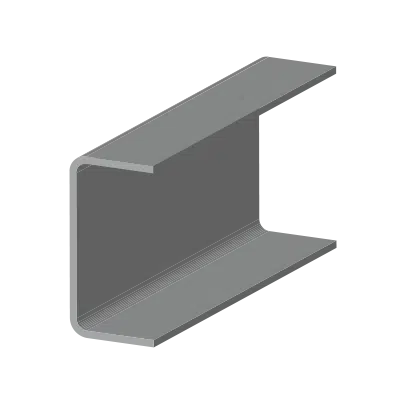

PFC Channel

| Minimum (mm) |

Maximum (mm) |

| 10mm x 10mm | 200mm x 200mm |

RSA Angle

| Minimum (mm) |

Maximum (mm) |

| 10mm x 10mm | 200mm x 200mm |

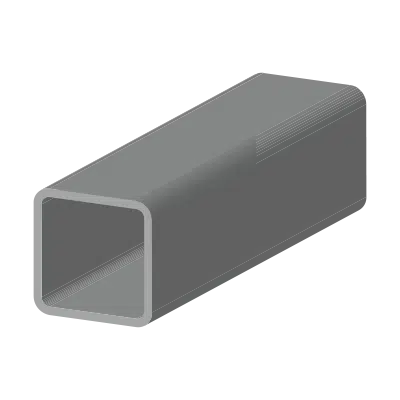

Rectangular & Square Tubes

| Minimum (mm) |

Maximum (mm) |

| 10mm x 10mm | 200mm x 200mm |

Round Tube & Pipe

| Minimum (mm) |

Maximum (mm) |

| Ø10mm | Ø220mm |

Start your custom design now

✓ EFFORTLESS AND SMOOTH EXPERIENCE

✓ SECURE PAYMENT PROCESS

✓ FAST DELIVERY SERVICE

Frequently Asked Questions

Have Questions?

A-Tech operates the latest version of the design software Autodesk Inventor and requires an IGES file format to cut your parts.

We work with a diverse range of materials including stainless steel, aluminium, carbon steel, and more. Our versatile capabilities allow us to cater to the specific requirements of different industries.

Turnaround times can vary depending on the complexity and volume of the order. However, our advanced machinery allows us to provide high-speed production without compromising quality. Contact us with your specific requirements for a more accurate timeline.

- Exceptional precision and accuracy: Laser technology allows for precise and intricate cuts, ensuring tight tolerances to +–0.25mm and excellent finish quality

- Efficiency: A quick and efficient process, tube laser cutting reduces production times and costs significantly.

- Complex shapes and designs: Tube laser cutting ensures the creation of complex shapes, designs, and configurations that other methods are simply not capable of.

3D profiling is a process that uses advanced laser technology to create intricate and detailed three-dimensional cuts. This allows for the production of complex parts with high precision, enhancing the functionality and design of your products.

The kerf of a laser cutting machine is considerably thinner than the kerf of a sawblade, so is therefore capable of extremely detailed and refined cutting when compared to other methods of material cutting; with a cutting tolerance of +-0.25mm.

At A-Tech, our laser cutting tolerances are unrivalled. With our new state of the art laser cutting machine, we are able to process metal bar lengths up to 8,000mm long, 210mm in diameter and 12mm in thickness.

Tube laser cutting offers a multitude of applications, typical industries include

- Automotive and transport

- Architecture and construction

- Furniture and interior design

- Manufacturing and fabrication

Yes, we offer comprehensive support from concept to completion. Our experts can assist with prototyping and design, ensuring your product is optimised for laser cutting and meets your specifications.

Yes, in addition to laser cutting, we provide secondary operations such as painting, welding, and assembly. This allows us to deliver a complete, ready-to-use product tailored to your needs.

You can request a quote or place an order by contacting us via phone at (+44) 1325304033, email at [email protected], or by filling out the contact form on our website. Our team will get back to you promptly to discuss your requirements.

Yes, our advanced machinery and efficient processes enable us to handle both small and large volume orders with ease. Whether you need a single prototype or a large production run, we can accommodate your needs.

For any additional questions or to discuss your project in detail, please get in touch with us. We’re here to help you every step of the way.